“In the pre-hospital arena (uncontrolled environment) the performance of a medical device is critical. When treating a patient trapped in an overturned vehicle or an elderly resident in an assisted living facility, medical equipment reliability is paramount.”

Lieutenant Joe Prendes

Miami-Dade Fire-Rescue

Introduction

Device durability is important in all medical fields, but perhaps most notably in the pre-hospital emergency medicine setting. A product must be able to withstand the rigors of a fast-paced, mobile environment. Emergency medicine is easily one of the most challenging environments with respect to testing the limits of medical equipment durability. For this reason, we selected a pre-hospital environment for this study. If pulse oximeter sensors are able to withstand the demands of daily use in a high-volume emergency rescue organization, durability and resilience in more controlled medical environments can be expected.

Setting

As one of the ten largest fire-rescue departments in the United States, Miami-Dade Fire Rescue (MDFR) maintains more than 65 fire-rescue stations and provides emergency response to all of the unincorporated areas of Miami-Dade County, including 30 municipalities. As a full service fire-rescue department, MDFR is committed to excellence

in every aspect of fire and life safety. In addition to training in fire suppression, all MDFR firefighters fulfill a minimum requirement of Emergency Medical Technician certification, with a majority obtaining a higher certification of Paramedic.

More than 80 percent of MDFR’s call volume is medical related, with every frontline emergency response vehicle equipped with a defibrillator. Rather than having a pulse oximeter built into the defibrillators, a choice was made to purchase stand-alone, hand-held pulse oximeters. By equipping the vehicles in this way, the investment in back-up devices is minimized. If an oximeter is damaged or broken, a replacement oximeter can be exchanged without requiring the full defibrillator to be pulled from service.

“The assessment of oxygen saturation has become a standard vital sign tool. Stand-alone pulse oximeters allow for any response unit to assess oxygen saturation, regardless of the level of care that unit is ‘licensed’ to provide.”

Lieutenant Joe Prendes

Miami-Dade Fire-Rescue

MDFR has used Nonin Medical pulse oximetry monitors and sensors throughout their organization since 2002 with more than 250 handheld units in the field today. Nonin was chosen for their proven record in providing durable, cost-efficient handheld oximeter devices. In addition to being carried onboard conventional MDFR fire and rescue units, pulse oximeters are carried on the following specialized MDFR vehicles: Air Rescue helicopters (four), Motorcycle Emergency Response Teams (MERT), two Fireboats and other Marine Operations response vessels, the Urban Search & Rescue Team (USAR-FLT-1), the Anti-Venom Response Team, and Ocean Rescue Bureaus (lifeguards).

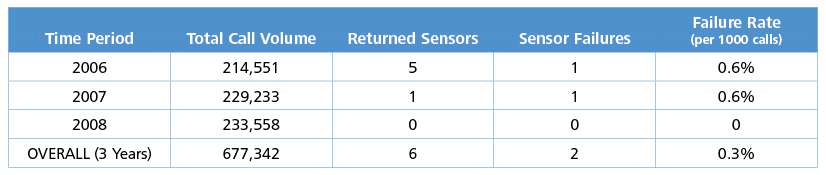

Table 1: Sensor Return Rates

Methods & Results

The present study is a retrospective review of the return rate and durability of Nonin’s 8000AA reusable sensor based on MDFR’s records and reports. A three-year study period was included and the monthly call volume was determined from facility records. Together this information was used to determine sensor return rates (see Table 1).

Over the course of the three-year study period, a total of six sensors were returned under warranty. Four of the six sensors returned were found to have no defects on inspection, leaving only two sensors with faults at time of return. The mode of failure for the two sensors was an exposed wire found on the molded end of the cable that attaches to the handheld pulse oximeter.

Discussion

Low Failure Rate. The large call volume at MDFR and extended customer records provided a unique opportunity to study the long-term durability of Nonin’s 8000AA reusable sensors in an uncontrolled, challenging environment. In this demanding setting with a wide variety of challenges, we found an extremely low sensor failure rate sustained over a three-year period. It is safe to assume that failure rates in less challenging environments can be expected to be even lower.

Mode of Failure: Exposed Wires. Exposed wires at the point of sensor cable connection is not an unusual mode of failure in the pre-hospital emergency field. Cables can easily be entangled or trapped on other equipment during transportation resulting in excessive force on the cable. In the pre-hospital setting, wrenching the sensor from the device via the cable may be unavoidable at times. Recognizing these inevitable demands of the environment, Nonin sensor cables are designed with an aramid fiber core. Aramid fibers are a class of strong, heat-resistant synthetic fibers used in military applications for ballistic bullet-proof rated body armor fabric. The aramid fibers are anchored at both ends of the sensor and provide a strong, stretch-resistant construction that protects the cable’s conductor wires from stretching forces.

Conclusion

Nonin’s 8000AA reusable sensor was found to have an extremely low failure rate as observed in the demanding, uncontrolled environment of pre-hospital emergency at MDFR. It is safe to assume that failure rates in less challenging environments can be expected to be even lower. Emergency rescue staff and health care professionals can be confident in the performance of Nonin devices when patient assessment is critical, resulting in efficient and appropriately administered care.

Oxygen saturation monitoring is an essential tool in the pre-hospital emergency response arsenal. By equipping rescue professionals with the proper tools designed to withstand challenging conditions, delays in patient care can be avoided and outcomes improved. This review demonstrates Nonin’s 8000AA pulse oximeter sensors exceed expectations of durability, enabling rescue professionals to provide a timely, accurate and complete patient assessment in any setting.